By Partners in the project Published

Bergen/Norway, Erlangen/Germany, Haugesund/Norway, 7 March 2023.

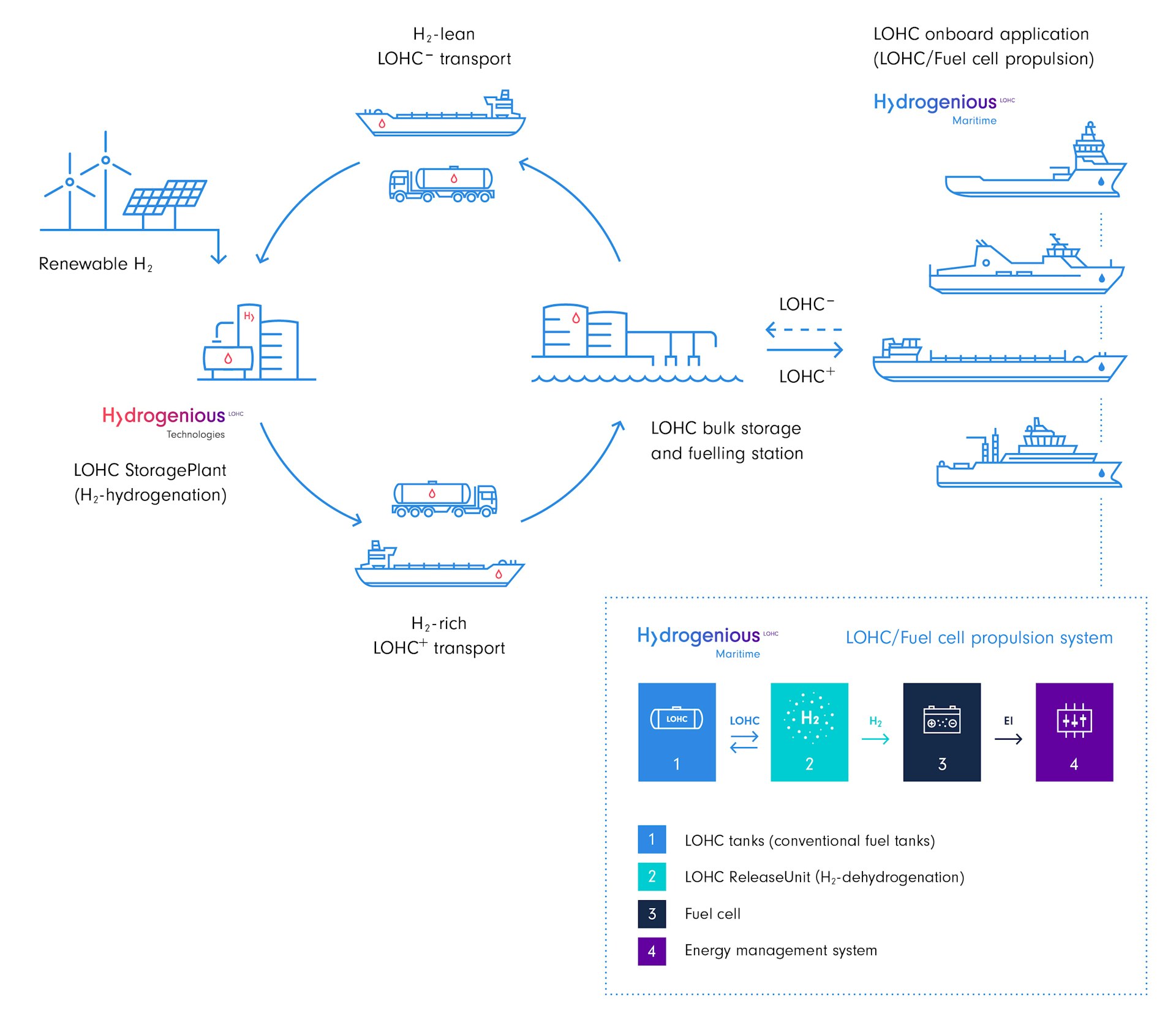

Alma Clean Power, Hydrogenious LOHC Technologies and Hydrogenious LOHC Maritime today announced a joint development agreement to engineer a fully integrated LOHC-SOFC (Liquid Organic Hydrogen Carrier-Solid Oxide Fuel Cell) power system for the Enova supported project “HyNjord”, focussing on a 100-kilowatt pilot powertrain to be demonstrated on board the Østensjø Rederi operated offshore supply vessel Edda Ferd. The agreements also open up for hydrogen-powered vessels on megawatt-scale later.

The innovation combines hydrogen release from the LOHC with direct conversion into power by an adjacent SOFC unit to the benefit of high efficiency. The key to this lies in using the SOFC device’s excess heat to meet the LOHC release unit’s heat demand. Hydrogenious’ LOHC solution provides a safe and easy method for handling hydrogen as a fuel, facilitating the decarbonisation of the maritime industry.

“With this partnership, we leverage synergies between Alma’s SOFC solution and our LOHC technology and take the next milestone in pioneering the use of hydrogen as a safe and efficient zero emission fuel to ships”, says Dr Daniel Teichmann, CEO and founder of Hydrogenious LOHC Technologies.

Øystein Skår, General Manager at Hydrogenious LOHC Maritime adds: “Our goal is to develop a zero emission power solution for shipping, and with this agreement we join forces to combine the LOHC technology with SOFC technology to develop an efficient way to produce power on board ships without emissions.”

Head of On-board Technology at Hydrogenious LOHC Technologies, Dr Holger Buech explains: „We’re very excited about this partnership, since it will allow us to develop and realise an integrated LOHC-SOFC system, which combines safe release of hydrogen from an easy-to-handle energy carrier with a fuel cell of high electrical efficiency. More than that, we will lift a special technological treasure by integrating the systems regarding their heat balances, thereby creating a thermal yin and yang of hydrogen technology.”

Hydrogenious LOHC Technologies is a global market leader of liquid organic hydrogen carrier (LOHC) solutions in the fields of hydrogen storage and transportation. Instead of using gaseous or liquified hydrogen, hydrogen is chemically bound to the carrier material benzyl toluene, a thermal oil. Hydrogenious LOHC Maritime utilizes this specific LOHC tech to assemble and market a shipshape LOHC-fuel cell powertrain, with compelling safety and handling advantages for shipping. The hydrogen is directly released on board from the LOHC in fuel cell grade.

Torleif Stokke, Head of Commercialization in Alma Clean Power, says: “The introduction of LOHC into the Alma world underpins our multi-fuel strategy, adding one more fuel on our list of opportunities for decarbonization of the shipping industry. Combining LOHC with our SOFC systems is an excellent way to make the best out of green hydrogen. The LOHC technology offers a safe means of transporting and storing hydrogen on ships, pushing the boundaries for using hydrogen effectively also in deep-sea shipping. Combined with our high-temperature SOFC technology, we can ensure high energy efficiency with zero emission operations. We’re excited to partner with Hydrogenious on such an important project, enabling this ground-breaking technology to reach the market and support ship owners on their decarbonization journey.”

Bernt Skeie, CEO in Alma Clean Power concludes: “We’re excited to partner with Hydrogenious on such an important project, enabling this ground-breaking technology to reach the market and support ship owners on their decarbonization journey.”

About the safety & economic advantages of Hydrogenious’ LOHC technology for shipping

Hydrogenious’ LOHC technology with benzyl toluene as carrier material (LOHC-BT) stands out due to its inherent characteristics: Hydrogen stored in the LOHC benzyl toluene is hardly flammable and non-explosive, ensuring very safe operations. The LOHC-BT has no discharge over time. Its hazard potential is even smaller than that for diesel.

It can be handled under ambient temperature and pressure (i.e., refuelling by pumping a liquid and use of conventional pumps). In addition, conventional liquid fuel infrastructure can be used, i.e., existing bunkering terminals in ports as well as on-board bunkering facilities.

By the thermal integration of LOHC and SOFC, fuel utilisation will be optimized, and thereby vessel range and economics can be maximized.

The hydrogen volumetric storage density is competitive with 54kg hydrogen per m³ LOHC. That will lead to easily carrying enough energy onboard to be able to operate in normal intervals of up to several weeks without refuelling. The carrier material benzyl toluene is commercially available and is reusable hundreds of times.

About Hydrogenious LOHC Technologies

Hydrogenious LOHC adds the missing link to high-performing hydrogen value chains globally. Based on its Liquid Organic Hydrogen Carrier (LOHC) technology with benzyl toluene as carrier medium, Hydrogenious LOHC allows for superior, flexible hydrogen supply to consumers in industry and mobility across the globe, utilizing conventional liquid-fuel infrastructure. Founded in 2013, the portfolio of the market-leading pioneer and its joint venture companies today includes stationary and mobile (on-board) LOHC-based applications: Hydrogenious LOHC Technologies, headquartered in Erlangen/Germany, offers – within an EPC partnership with Bilfinger – (de-)hydrogenation turnkey plants, Operation & Maintenance and LOHC logistics services – ensuring safe, easy and efficient hydrogen storage, transport and distribution. With its investors AP Ventures, Royal Vopak, Winkelmann Group, Mitsubishi Corporation, Covestro, JERA Americas, Temasek, Hyundai Motor Company, Chevron Technology Ventures and Pavilion Capital, Hydrogenious LOHC Technologies is a major enabler and accelerator for the energy transition.

About Hydrogenious LOHC Maritime

Hydrogenious LOHC Maritime treads a new path towards safe zero-emission shipping. The joint venture of Hydrogenious LOHC Technologies and Østensjø Group develops and markets an emission-free onboard propulsion system, based on a first-of-its-kind LOHC/fuel cell solution. One compelling competitive advantage besides its special safety: Hydrogenious’ Liquid Organic Hydrogen Carrier allows for utilizing existing bunkering facilities onboard as well as in the ports. Based in Norway, the arising supplier for a global sustainable shipping industry brings together congenial strengths of its two shareholders for the benefit of very safe, easy and cost-efficient decarbonisation of shipping: With its proprietary LOHC technology, the German Hydrogenious LOHC Technologies GmbH is changing the way to handle hydrogen, revolutionising the supply chain for green hydrogen also for the global shipping industry. The international market-leading pioneer holds a 70 percent stake and the Norwegian shipping group Johannes Østensjø dy AS contributes its international maritime expertise that has grown over decades and holds 30 percent of the company.

About Alma Clean Power

Alma Clean Power specializes in the production of high temperature Solid Oxide Fuel Cells (SOFC) for the ocean industries. The company’s technology builds on more than 30 years of experience with research and development of SOFC systems which are characterized by high efficiency and fuel flexibility. The technology can among others operate on fuels such as LNG, ammonia, methanol, ethanol, LPG, syngas and hydrogen. Alma’s SOFC technology has great potential to decarbonize deep-sea shipping as it can operate on hydrogen-based fuels with zero emissions, or on fossil-based fuels such as LNG with efficient carbon capture. The modular design enables innovation in new ship designs, and the technology's combustion-free nature ensures silent operation without any vibrations.

Alma Clean Power was launched as a venture from Clara Venture Labs in 2021 in Bergen, Norway, with an ambition to establish a full-scale production of fuel cells to support decarbonization of ocean industries. The company is currently in a pilot and demonstration phase to refine its technology and prepare for its upcoming commercialization, with the first full-scale products to be installed on vessels in 2025.

Alma Clean Power’s mission is to accelerate the transition to zero emissions in the ocean space.